Mechanical Bulk Material Handling Equipment

Shafted screw conveyors: Are used in thousands of industrial applications every day for efficiently conveying a variety of bulk materials. A screw conveyor’s main function is to transfer bulk materials from one process to another. Screw conveyors are very cost-effective and require minimal maintenance to operate.

Shaftless Screw Conveyors: Bulk materials discharged from centrifuges, filter presses or mixers can easily be metered or conveyed using a shaftless screw conveyor. Our shaftless design provides a non-clogging conveying surface that allows difficult-to-convey materials to become easy-to-convey. The perfect solution for handling bulk materials with high moisture content is the KWS Shaftless Screw Conveyor.

Vertical screw conveyors: Are a very efficient method for elevating a variety of bulk materials at very steep inclines or completely vertical. The compact design allows for the vertical screw conveyor to fit into almost any plant layout. With a minimum number of moving parts, the vertical screw conveyor is a cost-effective and dependable component of any bulk material handling process.

Live Bottom Bins: Screw feeders and live bottoms are one of the most accurate and efficient methods of metering bulk materials. Many processes begin with bulk materials being discharged from hoppers, bins or silos. The inlet area is flood-loaded and designed to meter bulk materials at fixed or variable rates. With our extensive knowledge and experience, KWS will provide a system to meet all of your requirements.

Belt conveyors: Are the most economical method of transporting bulk materials over both short and long distances. Belt conveyors are ideal for conveying bulk materials of large lump size since the bulk materials stay stationary on the belt. The layout of your plant can be simplified and made more efficient with the use of belt conveyors.

Drag conveyors: Are a great complement to screw conveyors and belt conveyors and a requirement of many bulk material handling applications. Drag conveyors can be used to meter or transfer bulk materials from one process to another. The compact and versatile design allows drag conveyors to fit almost any plant layout.

Heat Transfer Screw Processors: During the processing of many bulk materials, there is a requirement to cool, heat, or maintain a specific product temperature while conveying the product. The desired temperature fluctuations must be calculated and engineered into the system to accomplish the preferred objectives. KWS Heat Transfer Screw Processors are the perfect solution for these applications.

ASME Pressure Vessels: Many bulk solids processing applications require mixing of solids and liquids under both pressure and temperature to achieve a desired finished product. Pressure or vacuum can be applied to the internal portion of the vessel where the bulk solids are being processed. The bulk solids can be heated or cooled as required by external jackets that are integral to the vessel walls. KWS coded pressure vessels combine our knowledge of conveying and mixing with the science of heat transfer.

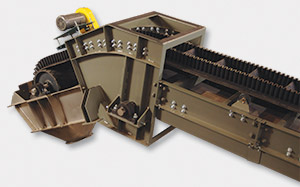

Bucket Elevators: Consist of a series of buckets attached to a belt or chain with pulleys or sprockets located at the top and bottom of the unit. The buckets are located in a casing or housing to contain the material. Bulk materials are loaded into each bucket as the bucket moves past an inlet point. KWS designs and manufactures a wide variety of bucket elevators based on the characteristics of the bulk material and the process requirements. Bucket elevators are designed to handle a wide variety of bulk materials from average to very free-flowing. Many different bucket and casing sizes available for capacities up to 15,000 cubic feet per hour, completely enclosed for dust and weather-tight operation.